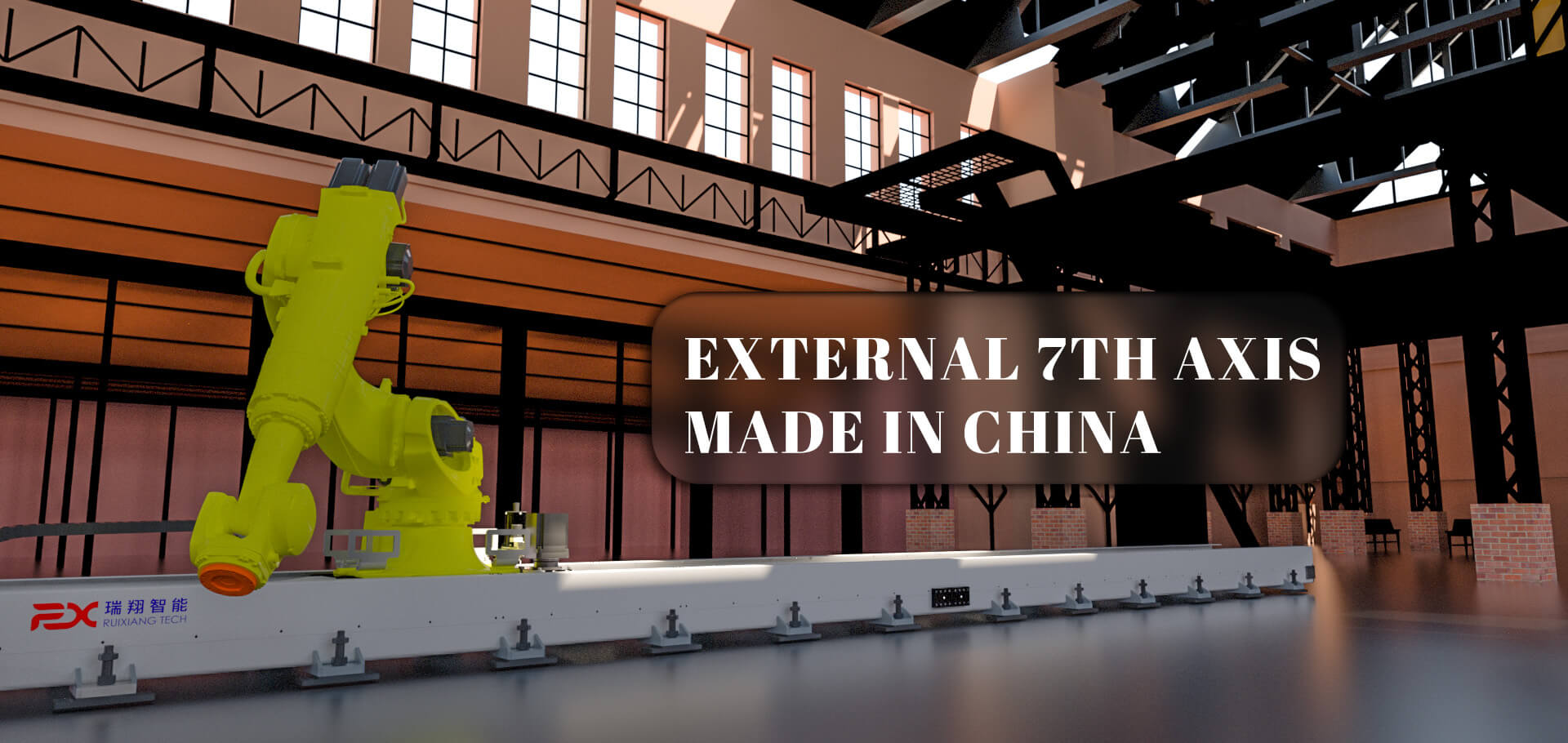

As manufacturing moves toward higher efficiency, higher stability, and greater flexibility, machining centers are gradually shifting from traditional manual loading and unloading to robot-centered automated production. In this transition, the combination of “Robot + Seventh Axis” has become one of the most valuable automation upgrade solutions in recent years, bringing higher productivity, lower labor dependence, and more stable product quality to factories.

In the past, machining centers relied heavily on manual loading, measurement, and material handling. This not only caused unstable efficiency but also increased safety risks. With the growing popularity of industrial robots, automated loading and unloading has become an industry necessity. The key trends include:

Upgrade from single-machine automation to full production-line automation

Transition from fixed-cycle production to flexible manufacturing systems (FMS)

Robots replacing manual handling for high-frequency, high-load operations

Multi-station and multi-equipment collaborative production

With the introduction of the robotic seventh axis, robots gain true long-distance mobility, allowing them to cover multiple machining centers and enabling full-line automation.

Core Values of the Robotic Seventh Axis in Machining Center Applications

1. Cover Multiple Machining Centers

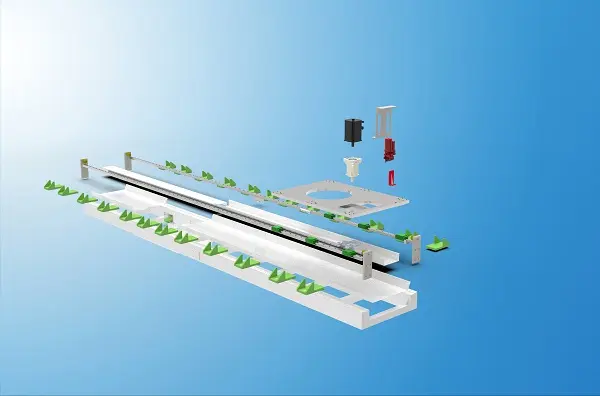

A single linear track can serve 2–10 machining centers. The robot moves along the seventh axis, enabling multi-machine sharing and greatly improving equipment utilization.

2. Achieve Flexible Scheduling

When switching products, the production line requires no major hardware changes—only program adjustments, improving flexibility.

3. Reduce Labor Costs

The system operates stably for long hours and does not require rest, making it ideal for night shifts and 24/7 continuous production.

4. Improve Loading and Unloading Efficiency

Robot motion is consistent and fatigue-free, reducing process fluctuations and minimizing issues such as dropped or damaged workpieces.

5. Support Heavy-Load Requirements

Heavy-duty seventh-axis systems allow robots from 100 kg to over 1000 kg to move smoothly, making them suitable for large and heavy-workpiece machining industries.

Why Are Factories Increasingly Relying on “Robot + Seventh Axis”?

For modern manufacturing companies, automation is no longer just about improving efficiency—it has become a core competitive advantage.

Rising labor costs make robot replacement a long-term trend

Unstable order volumes require flexible production capability

One robot serving multiple machines increases return on investment

Stable cycle time significantly improves product consistency and yield

24/7 reliable operation boosts overall equipment efficiency (OEE)

In the next 3–5 years, machining centers equipped with robots and seventh-axis systems will significantly enhance intelligent manufacturing levels and create a more competitive automated production model.