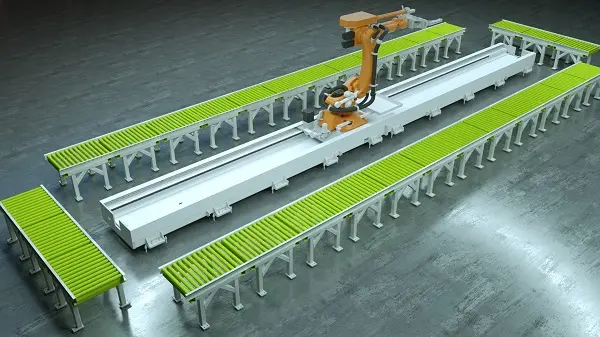

This solution is a heavy-duty automated loading and unloading system integrating an industrial robot seventh axis linear track with conveyor line linkage, suitable for continuous handling of medium and large workpieces, multi-station loading and unloading, and coordinated production line operations. The entire system is centered on a long-stroke heavy-duty traveling linear track, along which the robot moves to perform automated operations on both sides of the conveyor lines and multiple workstations, ensuring high-efficiency, stable, and continuous production cycles.

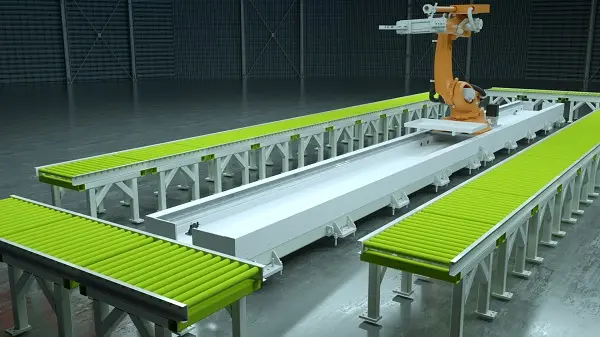

From the on-site layout, it can be observed that the center of the system is a heavy-duty industrial robot seventh axis traveling linear track. The industrial robot is mounted on the linear track carriage, with roller conveyor lines arranged on both sides of the track. The conveyor lines run parallel to the robot working area, forming a symmetrical production line layout. This configuration is highly suitable for long workstations, multi-cycle operations, and continuous loading and unloading processes, significantly improving the robot’s coverage range and overall production line utilization.

The traveling linear track features the following characteristics: the overall structure adopts a high-rigidity box-type design; multiple support points are arranged at the base, making it suitable for long-stroke installations; the wide carriage ensures stable operation of heavy-duty robots; and pre-designed robot mounting and positioning interfaces allow for fast and convenient installation. This structural design effectively addresses the challenges of rigidity, stability, and smooth operation under heavy-load conditions, making it suitable for long-term continuous operation in automated production lines.

This industrial robot seventh axis traveling linear track heavy-duty automated loading and unloading system achieves efficient and stable robot operation under long-stroke and multi-station working conditions through a well-engineered linear track structure and conveyor line integration layout. The solution is particularly suitable for manufacturing enterprises with high requirements for heavy loads, continuous operation, and production line coordination, serving as an effective solution for automation upgrades and capacity improvement. For customized designs based on stroke length, load capacity, and structural configuration, further discussion can be arranged according to actual operating conditions.