During the operation of automated production lines, as handling strokes become longer and workpiece weights increase, many engineers begin to notice that three-axis manipulators which previously ran stably may start to show vibration, reduced positioning accuracy, or insufficient structural rigidity.

These issues become even more pronounced in cantilever-type layouts.

In practical applications, you may encounter the following situations:

Once the stroke increases, the stability of the cantilever end begins to decline.

When the horizontal stroke becomes longer or a heavier end effector is installed, the system may experience:

slight vibration at the end position,

and positioning repeatability that does not meet expectations.

After long-term operation, positioning accuracy may gradually decrease.

These issues are not obvious under light loads, but will become increasingly significant in continuously running automated production lines.

As workpiece weight increases, the rigidity requirements for the linear module become significantly higher.

When handling heavier workpieces, you may observe:

unavoidable beam deflection,

concentrated loads on guide rails and sliders,

and increased sensitivity to installation and tuning accuracy.

If the structural rigidity is insufficient, long-term stable operation is difficult to achieve, even with conservative motion parameters.

When on-site space is limited, structural options become restricted.

In some production lines:

one side requires cantilevered operation,

a full gantry structure cannot be installed on the floor,

and conveyor lines or other equipment must be avoided.

In such cases, conventional gantry structures are not suitable, while cantilever solutions demand higher stability.

What application requirements is a cantilever auxiliary rail manipulator suitable for?

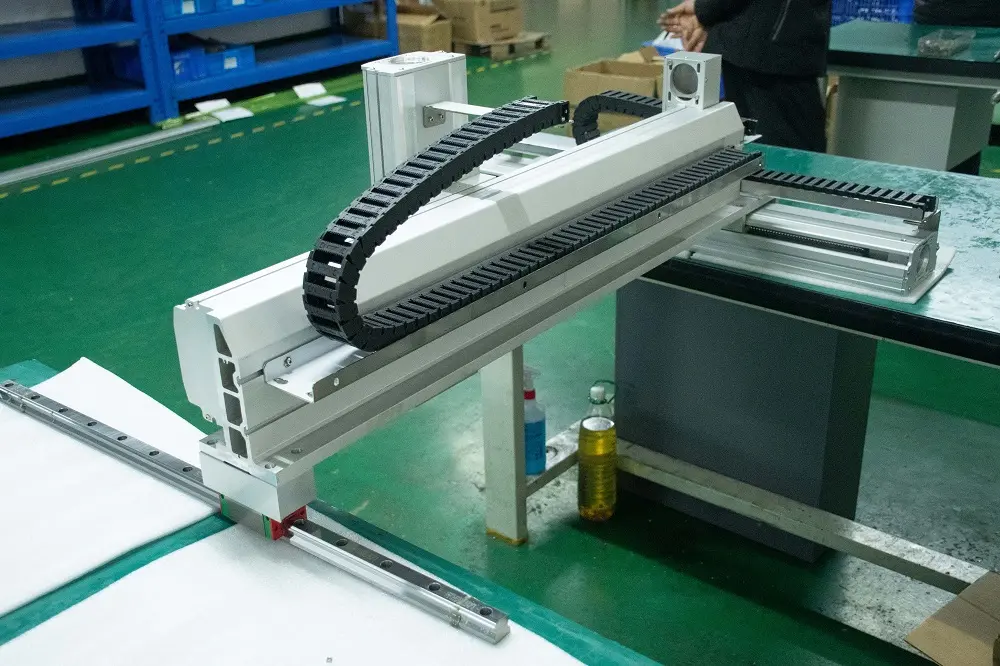

The cantilever auxiliary rail manipulator is a three-axis linear module solution that maintains the flexibility of a cantilever structure while improving overall stability by distributing loads through an auxiliary rail beneath the cantilever.

This structure is well suited for applications that require:

long strokes while maintaining a compact layout,

moderate loads with clear stability requirements,

long-term continuous operation rather than short-term demonstration use,

and improved reliability without significantly increasing structural complexity.

What practical improvements does this structure provide?

Smoother operation

With the auxiliary rail sharing the load, cantilever deflection is significantly reduced, resulting in smoother motion during acceleration and deceleration and improved cycle stability.

More stable accuracy retention

Under long-term operation and high-frequency reciprocating conditions, load distribution becomes more uniform, helping maintain consistent repeat positioning performance.

Better adaptability to on-site conditions

Compared with full gantry structures:

it requires less installation space,

offers more flexible mounting options,

and integrates more easily with conveyors, machine tools, and other equipment.

If your application requires both the flexibility of a cantilever structure and higher operational stability,

the cantilever auxiliary rail manipulator offers a three-axis linear module solution that is better suited for long-term stable operation.