During the selection of linear modules, many people have the same question:

Why can the same module carry 30 kg in horizontal use, but only 10 kg in vertical use?

Taking the RGTH5 embedded linear module as an example, we will explain the reasons clearly based on actual force conditions and structural principles.

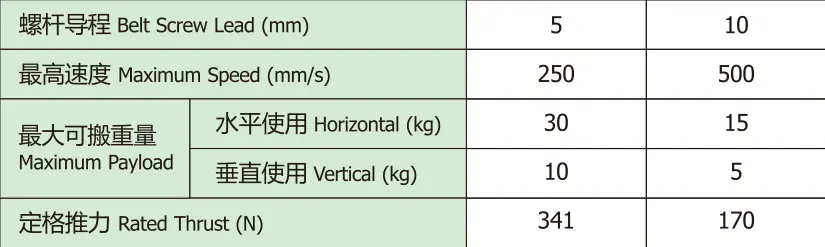

RGTH5 is available with 5 mm and 10 mm lead options, and the performance differences are as follows:

5 mm Lead Version

Maximum speed: 250 mm/s

Maximum horizontal load: 30 kg

Maximum vertical load: 10 kg

Rated thrust: 341 N

10 mm Lead Version

Maximum speed: 500 mm/s

Maximum horizontal load: 15 kg

Maximum vertical load: 5 kg

Rated thrust: 170 N

As shown above, regardless of the lead option, the vertical load capacity is approximately one-third of the horizontal load capacity.

Why is the vertical load significantly lower?

The force conditions are completely different.

Horizontal use

The load is mainly supported by the guide rails.

The drive system only needs to overcome friction and inertia, resulting in relatively balanced forces.

Vertical use

The weight of the load continuously acts on the ball screw nut.

The screw nut must constantly resist gravity, which is a long-term full-load condition.

Vertical applications require higher thrust.

This can be clearly seen from the specifications:

5 mm lead: 341 N thrust → supports higher vertical loads

10 mm lead: 170 N thrust → more speed-oriented, reduced vertical capacity

The larger the lead, the higher the speed, but the lower the thrust per unit.

This is why the 10 mm lead version has a vertical load of only 5 kg.

In actual selection, we focus more on the following factors:

• Installation direction (horizontal / vertical / inclined)

• Whether speed or thrust is required

• Stroke length and mounting method

For example:

High-speed horizontal handling → 10 mm lead is more suitable

Vertical lifting or heavy positioning → 5 mm lead is recommended

Choosing the wrong lead does not necessarily mean the module cannot move,

but it will affect service life, safety, and long-term stability.

We have prepared linear module selection reference materials,

which can be obtained by contacting our customer service.

If you have specific parameters (load, stroke, speed, installation direction),

you can also send them to us, and our engineers will assist with the selection to help you avoid choosing the wrong model or taking unnecessary detours.